How a $10 ream of paper saved a hospital ~$165,000

When a Labor and Delivery floor needed assistance investigating their long wait times, I was brought in to conduct an end-to-end process map. Through careful cross-functional observations, I discovered a bottleneck in the labs department and recommended a $10 analog solution that had the potential to save $164,250 a year in wait time costs!

Problem Details

Delivery delays and decreasing delivery numbers have been a problem for this hospital for several years. I was tasked with finding out why cesarean sections (C/S) were consistently delayed and recommend a solution. My research validated the previous efforts by internal hospital employees to determine a cause of the above problem as well as additional areas for improvement gone unseen by L+D staff.

Method

Secondary Research

Validate the problem exists by reviewing Qlik data on deliveries within a specified timeframe.

Educating myself on the process and protocol of a cesarean section to understand crucial background to better understand the problem.

Observing the relationship between Labs and L+D helped to understand the process of a STAT laboratory tests, or specimens collected that are needed immediately in order to manage medical emergencies.

Primary Research

Analysis

Combining primary and secondary research led to a breakthrough where a bottleneck in labs was discovered. When a STAT lab from L+D comes down a vacuum tube shoot, like you might see in the drive thru of a bank, it looks identical to all lab types coming from every department of the hospital. Qlik data revealed exactly how long it took for a lab tech to recognize one of the identical tubes as a STAT lab from L+D. This wait time was on average 6 minutes per lab with approximately 60-75 STAT labs a day. Comparing that with costs of staff waiting for lab results, this creates a costly delay.

Outcome

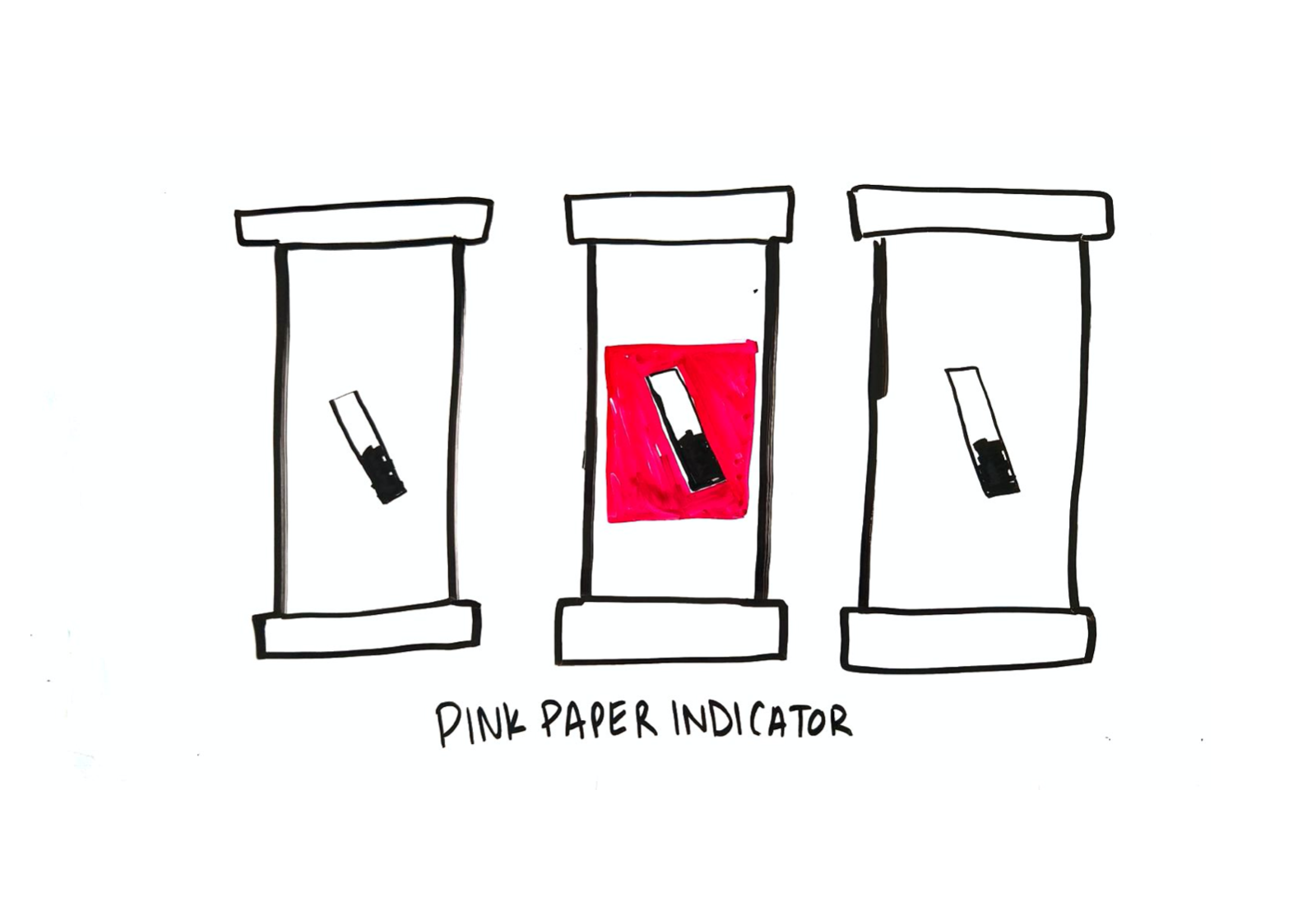

The solution was not digital, nor expensive. To guarantee a lab tech would see the STAT lab from L+D, we inserted a half sheet of pink paper into the clear tube alongside the specimen. The tube then stood out from the others and was processed first. This analog solution cost about $10 and shaved 6 minutes off the wait time for a STAT lab to be processed. The result was a potential savings of $164,250 a year.